Vijesti

DR.PAX YouTube

Razvoj proizvoda

Tražiš stručnjaka koji će tvoju ideju pretvoriti u stvaran proizvod? Na pravom si mjestu! Sa iskustvom od preko 10 godina u mašinskom inženjeringu i razvoju proizvoda, nudim kompletnu podršku – od početne ideje do finalne proizvodnje.

Nudim sljedeće usluge:

✔ Konceptualni dizajn – Razrada ideje kroz skice i 3D modele

✔ Razvoj proizvoda i inženjerski dizajn – Kreiranje funkcionalnih i optimizovanih rješenja

✔ Izrada prototipova putem 3D printanja – Brza validacija dizajna prije serijske proizvodnje

✔ Redizajn postojećih proizvoda – Poboljšanje performansi i smanjenje troškova

✔ Izrada tehničke dokumentacije – Priprema crteža i specifikacija za proizvodnju

✔ Razvoj i optimizacija proizvodnje – Priprema proizvoda za masovnu ili maloserijsku proizvodnju

Bilo da krećeš od nule, imaš ideju kao startup ili želiš unaprijediti postojeći proizvod, tu sam da ti pomognem ostvariti tvoju viziju uz stručnost i inovativni pristup!

3D Print

Treba vam ekspert za 3D printanje? Na pravom ste mjestu! Kao doktor nauka u ovoj oblasti, nudim profesionalne usluge 3D printanja, savjetovanje pri odabiru materijala i pomoć u uspostavljanju aditivne proizvodnje u vašoj kompaniji. Bez obzira na to da li vam je potreban prototip, funkcionalni dio ili proizvodnja aditivnim tehnologijama, osiguravam precizna i prilagođena rješenja.

Nudim sljedeće usluge:

✔ Dizajn i redizajn proizvoda za 3D printanje – Optimizacija postojećih rješenja za aditivnu proizvodnju

✔ Priprema proizvoda za 3D printanje – Pravilna prilagodba geometrije i strukture za optimalne rezultate

✔ 3D printanje različitim tehnologijama – FDM, SLA, SLS i druge napredne metode

✔ Odabir materijala za 3D printanje – Savjetovanje i selekcija materijala u skladu s vašim zahtjevima

✔ Izrada prototipova putem 3D printanja – Brza validacija dizajna prije proizvodnje

✔ Proizvodnja finalnih proizvoda 3D printanjem – Precizni i funkcionalni gotovi dijelovi

✔ Uspostavljanje tehnologije 3D printanja u kompaniji – Implementacija i optimizacija aditivne proizvodnje

Bilo da razvijate novi proizvod, prilagođavate postojeći ili želite unaprijediti proizvodne procese, tu sam da vam pomognem sa stručnim i efikasnim rješenjima!

3D Print u medicini

Sa svojim timom već više od pet godina radim na primjeni 3D printanja u medicini, pružajući visokokvalitetna rješenja za medicinske stručnjake. Koristimo napredne tehnologije kako bismo osigurali preciznost i funkcionalnost u različitim oblastima medicinske primjene.

Nudimo sljedeće usluge:

✔ 3D printanje implantata

✔ Izrada 3D modela kostiju iz DICOM datoteka

✔ 3D printanje preoperativnih modela kostiju ili organa

✔ 3D printanje hirurških vodiča

✔ 3D printanje anatomskih modela

✔ Razvoj različitih trening modela primjenom tehnologija 3D printanja

Naša rješenja omogućavaju bolju pripremu za operacije, precizniju dijagnostiku i efikasniju edukaciju u medicini. Ako vam je potreban pouzdan partner za 3D printanje u medicini, tu smo da vam pomognemo!

Edukacije

Kao Solidworks Champion i stručnjak sa preko 10 godina iskustva u edukaciji, obučio sam više od 1000 studenata i inženjera, prenoseći znanje iz oblasti 3D dizajna i 3D printanja. Također, kao pionir 3D printanja u Bosni i Hercegovini, doktor nauka iz oblasti 3D printanja i aditivne proizvodnje, te autor preko 20 naučnoistraživačkih radova iz oblasti 3D printanja, pružam stručnu edukaciju iz oblasti 3D printanja. Pružam edukaciju razvoja proizvoda – od koncepta do prototipa. Spreman sam da vas podučim kako efikasno koristiti Solidworks za 3D dizajn i primijeniti 3D printanje u industriji.

Nudim edukacije iz sljedećih oblasti:

✔ Solidworks 3D dizajn – CAD 3D Modeliranje

✔ 3D printanje – Izrada prototipova i funkcionalnih dijelova različitim aditivnim tehnologijama

✔ Priprema proizvoda za 3D printanje – Optimizacija dizajna za aditivnu proizvodnju te izbor parametara 3D printanja

✔ Razvoj proizvoda od ideje do prototipa – Integrisan proces od dizajna do finalne izrade

✔ Edukacija i konsultacije iz oblasti 3D printanja i aditivne proizvodnje

Bilo da želite savladati Solidworks 3D dizajn, naučiti 3D printanje ili razviti vlastiti proizvod, tu sam da vam prenesem znanje i pomognem u svakom koraku razvoja!

Edukacije

O meni

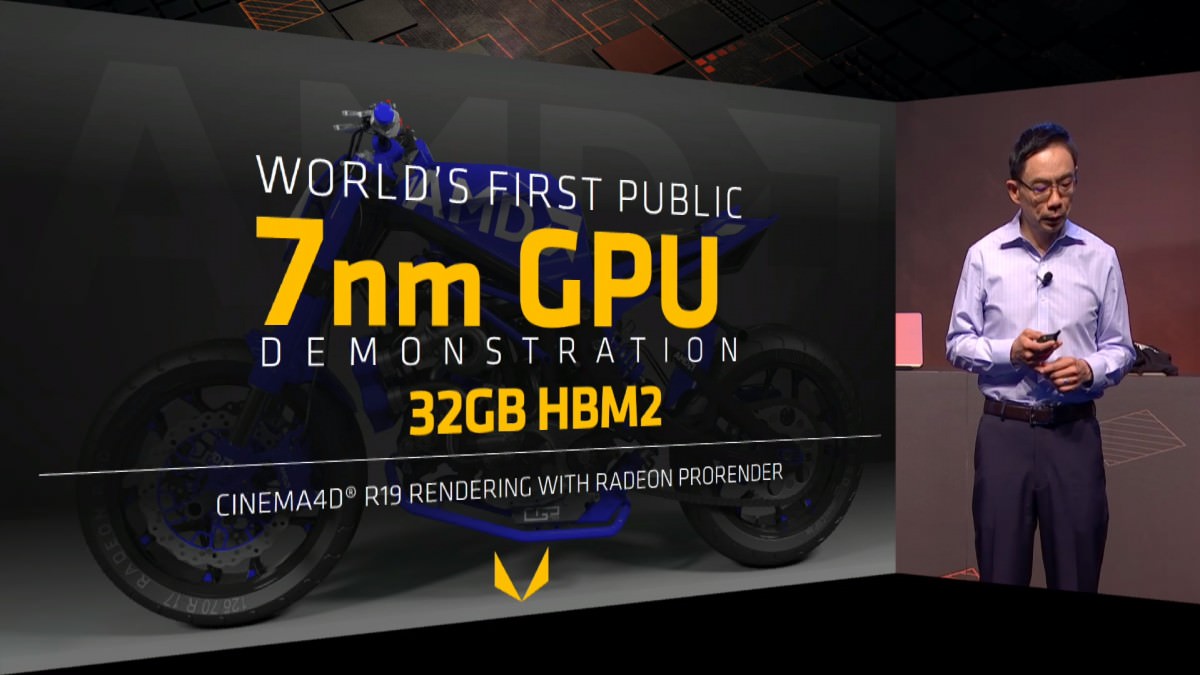

Adi Pandžić je doktor nauka iz oblasti mašinskog inžinjerstva sa specijalizacijom u materijalima za 3D printanje. Također, i docent na Mašinskom fakultetu u Sarajevu, koordinator za ispitivanje materijala – Laboratorija za ispitivanje polimernih materijala. Stručnjak je u oblasti 3D dizajna (Solidworks) i 3D printanja. Kao produkt dizajner, radio je za kompanije kao što su NVIDIA, AMD, Intel, HP, EpicGames (Unreal Engine), Dassault Systemes i mnoge druge. Ima iskustva u radu sa više od 1000 studenata kao edukator/mentor. Godine 2015. osvojio je "Grabcad Golden Gear Award" kao mentor i glavni dizajner sa svojim timom studenata, u konkurenciji sa više od 4 miliona inženjera i dizajnera. 2018. godine osvojio je "Projekt godine 2018" kao najbolji projekt dizajniran pomoću Solidworks-a. Također, 2022. godine, kompanija Ultimaker prepoznala je moj rad u oblasti 3D printanja, te sam bio na "Ultimaker Innovators listi 2020". Radio sam sa velikim brojem startupa širom BiH, koji su danas prerasli u ozbiljne kompanije.

SOLIDWORKS CERTIFIKATI:

CSWA, Associate Additive Manufacturing

CSWA, Solidworks Associate Mechanical Design

CSWP, Solidworks Professional Mechanical Design

SOLIDWORKS CHAMPION